The automatic laminated glass production line adopts advanced industrial Ethernet network communication mode and is centrally controlled by PLC assisted computer. All display and operation are on the touch screen of the clean room control box. The hardware based on Siemens ensures the efficiency and stability of the entire system. The inverter controls all the motors to ensure the stability of high-speed acceleration and deceleration. Non-contact sensors ensure sensitive response, high accuracy and no wear in transmission. The glass autoclave uses a fully intelligent TPC control system to automatically complete the entire production process according to the set temperature and pressure curve.

• The whole line PLC automatic control, frequency conversion speed regulation, accurate positioning.

• Fast automatic loading

• High-speed cleaning and drying, to meet a variety of coated glass cleaning

• Glass automatic positioning, automatic closing, positioning accuracy ≤0.5mm

• Independent drive convection roller press

• Glass tank special TPC control system to ensure the process curve

• The entire electrical line meets various safety standards such as UL/CE

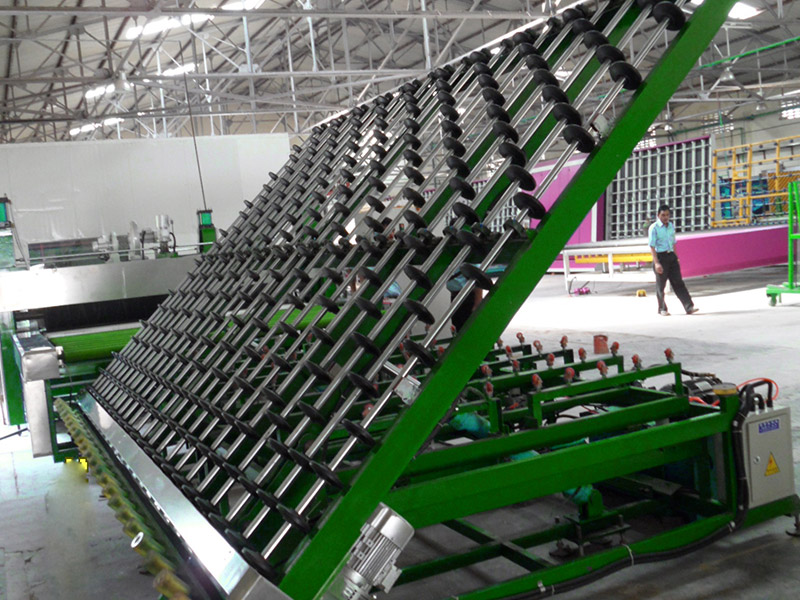

Automatic loading machine

High speed glass washing and drying machine

Automatic positioning table

Automatic sucker hanger machine

Automatic retracting film paver

Independent drive convection roll press

Flip the unloading table

High efficiency forced convection autoclave

Product parameter

Model

| Max Size (mm) | Min size (mm) | Thickness (mm) | Power(KW) | (4+0.38+4) Capacity (M2//8h) |

SN-JCX2060A | 2000X6000 | 420X300 | 4-80 | 302.5 | 1200 |

SN-JCX2560A | 2500X6000 | 420X300 | 4-80 | 354.5 | 1500 |

SN-JCX2580A | 2500X8000 | 420X300 | 4-80 | 390 | 1800 |

SN-JCX3080A | 3000X8000 | 500X400 | 4-80 | 568 | 2000 |

SN-JCX3380A | 3300X8000 | 500X400 | 4-80 | 612 | 2350 |