Introduction

A polymer plastic film material is sandwiched between two or more pieces of glass, and after initial pressing, it is then entered into the autoclaves for adequate heating and pressure treatment, and a glass synthetic product is obtained, which is called safety laminated glass. The various raw materials that make up the sandwich products, especially the process of the intermediate film in the autoclave, are very important to obtain a high quality product. The role of our forced-convection glass autoclaves is to ensure that the quality requirements of this product are met. Its stability and the production process in the autoclaves ensure that the finished product meets and continues to maintain the high quality standards required.

Overall overview and process of forced convection glass kettle

1. Overall characteristics

The glass autoclave is a pressure vessel with sealed forced convection internal circulation heating, in which temperature, pressure and vacuum are effectively controlled. The temperature and pressure achieved according to the set process curve can be obtained; Suitable for the synthesis of laminated glass with various process requirements. In particular, the intermediate film is PVB or SGP material products, and can ensure perfect product quality and yield.

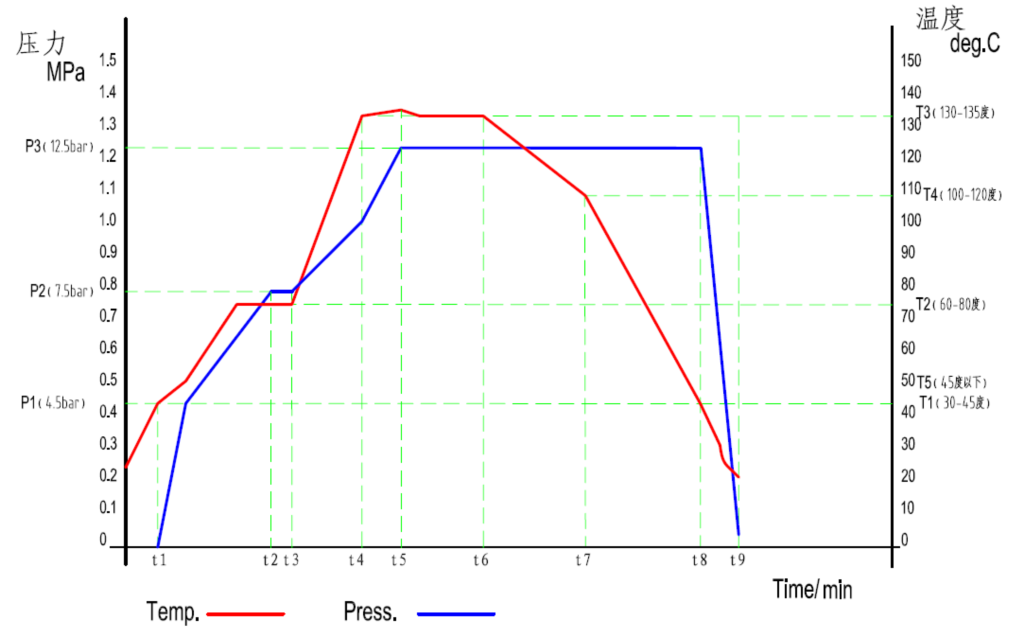

The standard working process of building glass autoclave has nine stages, including preheating and prepressing stage, initial heat preservation and pressure preservation stage, heating and pressure compression stage, final heat preservation and pressure preservation stage, step by step cooling stage, pressure relief stage, etc. Temperature and pressure are monitored by HIM at any stage, and the entire operation process is fully automated with the exclusive development of TPC (Thermal Processing Control) software based on the PLC control system.

2. Working curve

3. The process

temperature | stress | vacuum | cooling | Stage time | |

The first stage | T1 | 0bar | ON/OFF | OFF | t1 |

The second stage | T2 | P2 | ON/OFF | OFF | t1-t2 |

The third stage | T2 | P2 | ON/OFF | OFF | t2-t3 |

The fourth stage | T3 | P2 | ON/OFF | OFF | t3-t4 |

The fifth stage | T3 | P3 | ON/OFF | OFF | t4-t5 |

The sixth stage | T3 | P3 | ON/OFF | OFF | t5-t6 |

The seventh stage | T4 | P3 | OFF | ON | t6-t7 |

The eighth stage | T5 | P3 | OFF | ON | t7-t8 |

The ninth stage | T5 | 0bar | OFF | ON | t8-t9 |

|

Prev:

Application and principle of curing furnace

Next:None! |

Return |