Rubber vulcanization autoclave is the process of chemical cross-linking of rubber macromolecules under specific temperature, pressure and time conditions. The purpose is to make the rubber material flow easily and fill the mold cavity. Improve the density of the compound and the physical and mechanical properties of the finished product.

Vulcanization tank is the earliest vulcanization equipment used in the production of rubber products, mainly used for vulcanization of non-model rubber products, such as rubber shoes, hose, cable, rubber roller, rubber cloth, ball, rubber lining, and sometimes also used for vulcanization of model rubber products.

• Steam canister

• Electrically heated canister

• Heat transfer oil canister

Technical characteristics

Our canisters are preferred for technology and experience in the field of tire retreading and roller vulcanization

In order to obtain high quality roller products, it is very necessary to vulcanize the products directly coated with rubber on the metal as a support. Generally, this modification treatment is carried out in the vulcanization tank, in which the pressure, temperature and time can be effectively controlled without the need for molds. In this field, we are pioneers in technology and experience, as we have many years of experience in the production of rollers and have mastered the vulcanization process for a large number of different rubber formulation coating projects.

Benefits of TPC process control software

Our vulcanization tank is equipped with advanced thermal process control (TPC) system, which is developed on the basis of absorbing the advantages of various control systems at home and abroad, and is a very popular control system. The system has user rights login, sensor selection, vulcanization process curve setting, calling, saving, printing, process automatic, manual execution, real-time data monitoring, recording, saving, printing, each component status monitoring, alarm, quality analysis, reports and other basic functions.

PLC+HIM or PLC+PC system is available

Type of canister

Direct heating type canister

The steam vulcanization tank is arranged at the bottom of the steam diffusion tube, the steam enters the diffusion tube in the tank by the air inlet at the bottom of the tank, and the steam holes in the diffusion tube (Ø4 or Ø5mm) are densely arranged according to certain rules and inclined angles, so that the steam can be evenly spread around after entering the tank to ensure that the temperature in the vulcanization tank is uniform and there is no dead Angle; Prevent uneven heating of products caused by uneven steam diffusion and direct heating of rubber by steam. Direct steam heating and pressurization, temperature uniformity is usually +/ -1 °C, this heating system is very efficient, especially for vulcanizing large size and relatively heavy rubber products.

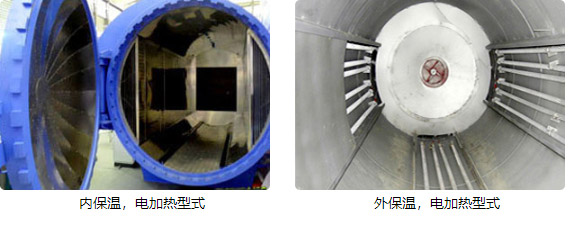

Electric heating canister (electric heating, compressed air pressure)

At present, electric heating vulcanization tank is our leading product, this heating method is efficient, energy saving and convenient. For most rubber products that can accept electric heating, he can make the vulcanization process strictly execute according to the preset process curve, and better quality products can be obtained. The electric heating vulcanization tank is made of special stainless steel electric heat pipe, built-in new thermal insulation oxidized rice material, heating fast, long service life; All wiring terminals of the electric heating tube are external to avoid heating and igniting of the internal wiring and improve the safety of the heating system. The hot air obtains uniform temperature through special hot air circulating fan and suitable air duct, and the pressure can be controlled independently, solving the problem that the quality of the products in the tank is not the same due to the uneven temperature and pressure.

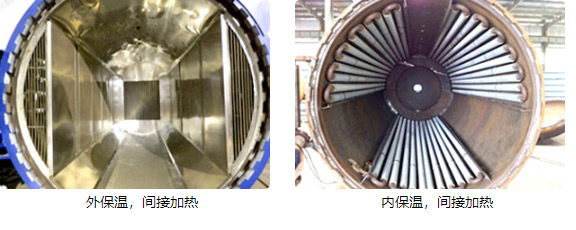

Indirectly heated canister (steam or thermal oil indirectly heated, compressed air pressurized)

Indirect heating vulcanization tank, indirect heating with steam or thermal oil, heat exchange is carried out in the heat exchanger in the vulcanization tank, generally used in large metal core roller vulcanization occasions and places where the power supply is insufficient. In order to prevent the thermal conductivity difference between the metal core and the rubber, the general vulcanization is more slowly heated and pressurized, and the vulcanization time is much longer than the vulcanization time required by the rubber itself, and the degumming between the rubber roller and the metal core is avoided due to different shrinkage. The heat generated by the heating system heats the air in the tank, and then the hot air obtains a uniform temperature through the special hot air circulating fan and the appropriate air duct, and the pressure can be independently controlled, solving the problem that the quality of the products in the tank is not the same due to the uneven temperature and pressure, which is the same as the electric heating vulcanization tank.

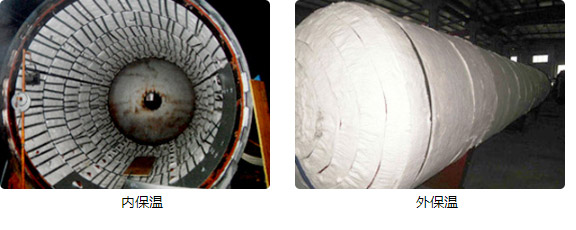

Insulation of vulcanization tank

Warm inside and warm outside

We use ceramic fiber as insulation material, the heat transfer coefficient is very low, the heat loss is reduced to a small. The sealing plate of insulation layer is made of stainless steel, beautiful and corrosion-resistant. The internal insulation energy consumption is low, and the external insulation must heat the entire kettle body each time it is heated, which has higher energy consumption, but can obtain higher temperature uniformity.

Hot air circulation system of vulcanization tank

Hot air circulation for electric and indirect heating

Impeller using improved centrifugal impeller, large air volume, high wind pressure. In the dynamic seal mixing, we use mechanical seal, silicon carbide - graphite as static ring sealing material, improve the service life; In terms of air duct design, we adopt U-shaped air duct structure, and there are diversion devices at the extension of the air duct, which can ensure the sufficiency of hot air circulation, make the forced convection efficiency in the tank reach more than 90%, and ensure the rate and uniformity of temperature rise.

High quality components and materials

In order to ensure the quality of the autoclave, we are under the guidance of strict process construction, each process, we are carefully manufactured, for the quality of the parts, we are pursuing very good.

Dimensions and operating conditions

We can design and manufacture canisters of any size required by our customers. We have extensive experience in the construction of canisters in different sizes (from 1 meter in diameter 0.8 meters to 30 meters in diameter 4.5 meters) in the factory.

Complete auxiliary system

We can provide our customers with a variety of auxiliary equipment for canisters, including vacuum systems, preheating systems, air compressor systems, water vapor exchange cooling units, component loading/unloading truck systems and mounting components.

Global service, meet a variety of product manufacturing standards

We can design and manufacture glass kettle for our customers according to different standards, the optional standards are as follows:

• China Standard GB150-2011;

• ASME SEC VIII DIV.1 with ASME Certificate;

European standard PED 97/23/EC with CE certificate;

• German standard AD2000 etc

Turnkey works available

Our team can provide you with turnkey projects, you do not need to worry about the installation of unprofessional, we will complete the installation and debugging according to your specific requirements, while conducting a professional training, to solve your worries.

Product parameter

Model | Effective diameter | Effective length | Applicable size |

SN-LHGR08 | 800 mm | 1000/1500/3000/4500 mm | Small size rubber production |

SN-LHGR10 | 1000 mm | 1000/1500/3000/4500 mm | Small size rubber production |

SN-LHGR15 | 1500 mm | 2000/4000/8000/12000 mm | Small size rubber production |

SN-LHGR20 | 2000 mm | 4000/6000/12000 mm | Middle size rubber production |

SN-LHGR25 | 2500 mm | 5000/8000/12000 mm | Middle size rubber production |

SN-LHGR28 | 2800 mm | 6000/8000/15000 mm | Middle size rubber production |

SN-LHGR30 | 3000 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGR32 | 3250 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGR35 | 3500 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGR40 | 4000 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGR45 | 4500 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGT1504 | 1500 mm | 1500 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT1506 | 1500 mm | 2250 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT1508 | 1500 mm | 3000 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT1512 | 1500 mm | 3750 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT1520 | 1500 mm | 7000 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT2045 | 2000 mm | 4300 mm | Construction machinery tire repair,Large size Max.23.5R25 |

SN-LHGT2550 | 2500 mm | 5200 mm | Construction machinery tire repair,Large size Max.29.5R25 |

SN-LHGT2845 | 2850 mm | 4500 mm | Construction machinery tire repair,Large size Max.24R49 |

SN-LHGT3260 | 3200 mm | 6000 mm | Construction machinery tire repair,Large size Max.33R51 |

SN-LHGT4080 | 4000 mm | 8000 mm | Construction machinery tire repair,Large size Max.55/80R57 |

Other specifications can be customized