In the middle of two or more pieces of glass sandwiched into a polymer plastic film material (polymer VBSGP), after initial pressing and then into the glass autoclaves for adequate heating, pressure treatment, and obtained a glass synthesis product, known as safety laminated glass. The various raw materials that make up the sandwich products, especially the process of the intermediate film in the glass autoclave, are very important for obtaining a high quality product.

• TPC system software based on PLC control, automatic control, stable and safe

• U-shaped, annular and other convection structure design, to ensure uniform temperature, improve yield

• Nickel-chromium alloy heating element, high life, high electric heating conversion efficiency, heating power ratio output efficient energy saving.

• Independent main cooling and auxiliary cooling systems to improve cooling efficiency while achieving accurate linear control of the cooling gradient;

• Variety of heating systems, can be electric heating, steam heating or thermal oil heating;

• With mechanical, electronic and software triple safety interlock protection;

• Suitable for safety laminated glass, automotive laminated glass, photovoltaic module packaging, BIPV production;

Technical characteristics

Continuous technological innovation ensures that the technology is at a new level, and our glass kettle has the following important characteristics:

• Precise temperature and pressure control according to process requirements based on user-specific product specifications;

• With online power consumption monitoring device, automatically store a working cycle of electricity consumption, convenient for user cost statistics and analysis;

• Optimized air duct structure, efficient circulating fan, superior thermal insulation system and intelligent temperature control regulation, to ensure the uniformity of temperature in the reactor and greater energy saving effect;

• Designed to meet the requirements of the homogenizing furnace, our glass kettle can be used as both a preheating chamber and a homogenizing furnace;

• High quality materials, high standard manufacturing, more secure and stable equipment;

• Use fully sealed special circulation fan, no leakage, maintenance-free;

• Independent main cooling and auxiliary cooling systems to improve cooling efficiency while achieving accurate linear control of the cooling gradient;

• Variety of heating systems, can be electric heating, steam heating or thermal oil heating;

• With mechanical, electronic and software triple safety interlock protection;

• Developed TPC control software based on PLC control, which can realize manual, automatic and redundant operation of process control, and can access the local area network and enter the DCS system of the factory to realize centralized control and management;

• Industrial computer, touch screen or controller can be selected as the upper computer to achieve process monitoring;

• Additional auxiliary equipment such as storage tanks, air compressors, vacuum systems and cooling stations can be included, and the entire auxiliary system can be monitored.

We can design and manufacture a variety of quick-opening structure glass kettle for customers

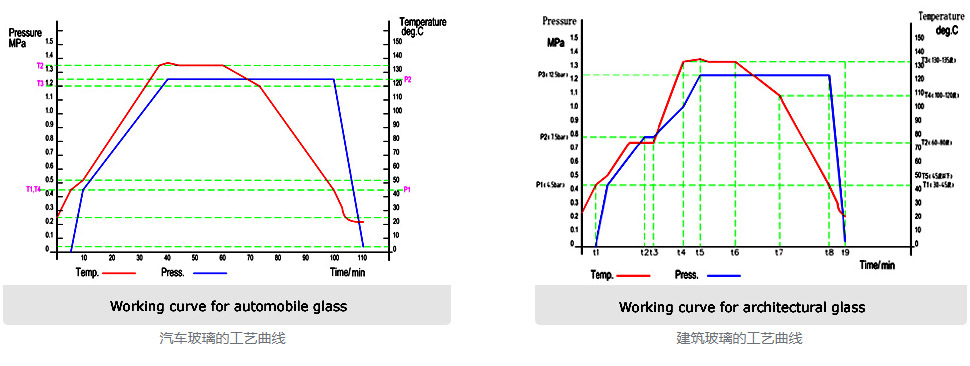

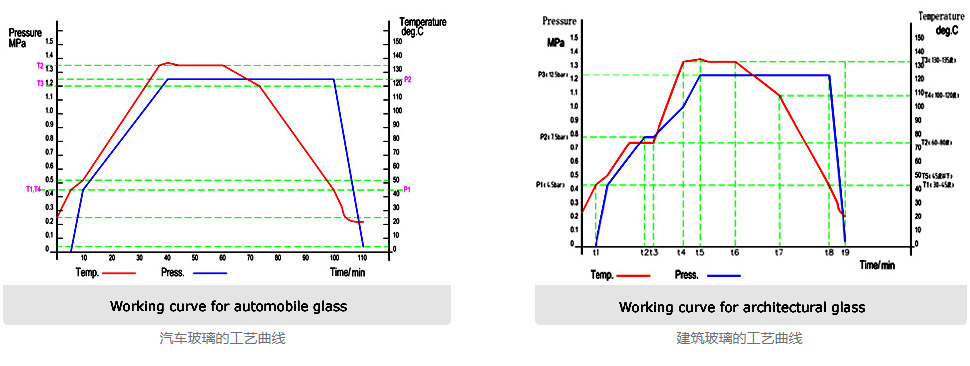

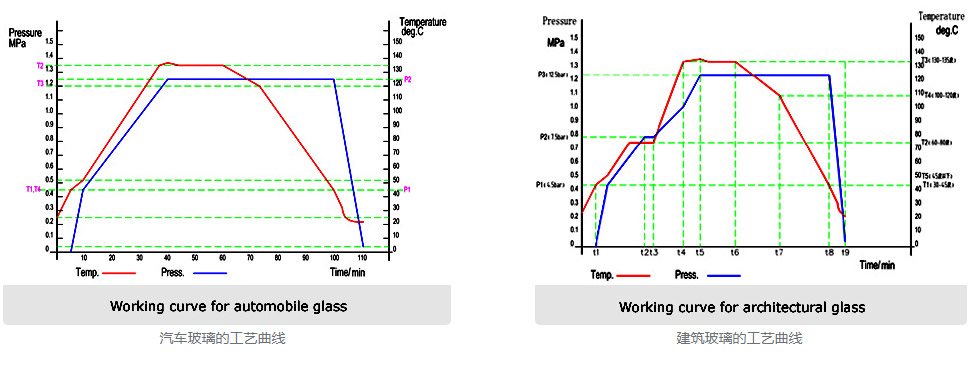

The process of glass autoclave

The entire process of the glass autoclave has 9 stages, and the temperature and pressure of each stage are independently monitored by HIM or PC. The whole process is realized by the PLC-based TPC control software developed by us to ensure that the entire process can be fully automatic one-click operation.

Excellent comprehensive performance of glass autoclave, saving 30% energy for customers

A variety of heating methods for glass autoclaves

The standard heating method of our glass kettle is electric heating, and the heating element is a nickel-chromium alloy heater. In order to meet the needs of different customers, we can also design other heating methods, such as steam heating, thermal oil heating, natural gas heating and so on.

Glass autoclave variety specifications

We can design and manufacture various sizes of glass kettle to meet different customer needs. The diameter can range from 1.5 meters to 4 meters, and the length can range from 1 meter to 21 meters.

Auxiliary system of glass autoclave

A glass kettle without an auxiliary system is an incomplete system. The auxiliary systems we can design and supply for glass reactors include: vacuum systems, pressurized systems (compressed air and nitrogen), closed cycle cooling systems, etc.

Multiple manufacturing standards to meet the needs of the global market

We can design and manufacture glass autoclaves for our customers according to different standards, optional standards are as follows:

Chinese standard GB150-2011;

ASME SEC VIII DIV.1 with ASME Certificate;

European standard PED 97/23/EC with CE certificate;

German standard AD2000.

Russian certified EAC, etc

We can provide turnkey engineering services to our users

We can provide the user with a turnkey project of the entire laminated glass. From the project planning, design, production, installation and after-sales service, we present a complete set of reasonable solutions for users with its very professional ability. Users can completely rest assured that the entire laminated glass project to us, we will according to customer requirements to complete the quality and quantity of design and production, guidance installation, system commissioning, on-site training and later after-sales service.

Product parameter

Model | Autoclave diameter | Effective length | Glass size | Design pressure | Design temperature | Heating power |

SN-BGF2040 | 2000mm | 4000mm | 1700*4000mm | 1.5Mpa | 160℃ | 96KW |

SN-BGF2550 | 2500mm | 5000mm | 2200*5000mm | 1.5Mpa | 160℃ | 135KW |

SN-BGF2650 | 2650mm | 5000mm | 2350*5000mm | 1.5Mpa | 160℃ | 144KW |

SN-BGF2860 | 2850mm | 6000mm | 2500*6000mm | 1.5Mpa | 160℃ | 162KW |

SN-BGF3080 | 3000mm | 8000mm | 2700*8000mm | 1.5Mpa | 160℃ | 225KW |

SN-BGF3380 | 3350mm | 8000mm | 3000*8000mm | 1.5Mpa | 160℃ | 297KW |

SN-BGF3690 | 3650mm | 9000mm | 3300*9000mm | 1.5Mpa | 160℃ | 352KW |

Other specifications can be customized